Learn how to use standard hotfix applicator on our YouTube Channel![]()

We recommed using a heat press, domestic iron or hotfix applicator in the Hotfix application:

Some textiles and special finishes are unsuitable for Hotfix application due to a lack of absorbency.

The following carrier materials and finishes are unsuitable for this type of application:

• very tightly woven textiles

• very thin fabrics, e.g., tulle

• smooth leather and smooth imitation leather

• hydrophobic or water-repellent treatments (silicone, synthetic resin as a waterproofing agent)

• Teflon® coatings

• stain-resistant treatments

• easy-care treatments

• fluorocarbon finishes

• softening agents

• some dyes (dyes with metal pigments)

• enzymatic treatments.

APPLICATION

BASIC HOTFIX PRINCIPLES

Hotfix elements have a coating of hot-melt glue on the back, enabling swift, simple application. This glue is activated by heat (applied either directly or indirectly via ultrasound), and bonds with the carrier material.

When cooling, the glue hardens and securely and permanently fixes the elements in place. The Swarovski Hotfix adhesive is characterized by its wash resistance and easycare properties. The temperature, application time and pressure can be varied according to the carrier material. Further details and information can be found in the “Care Instructions” chapter.

MATERIAL CHECK

Before beginning the application process, you should always check whether the carrier material is suitable for Hotfix application.

Please check the following criteria:

−− Heat resistance (min. 120 °C/250 °F)

−− Resistance against pressure

−− Application area of the product

−− Suitability of surface properties and absorbency

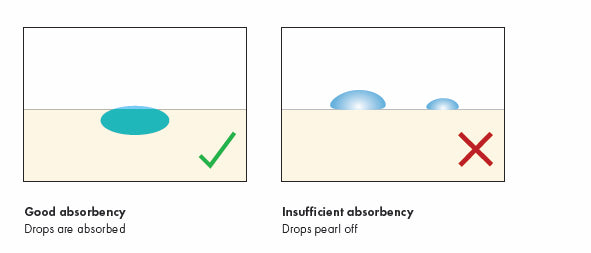

CHECKING ABSORBENCY VIA THE WATER DROP TEST

The water drop test is a quick and easy way to get an initial idea of the absorbency of the carrier material.

Apply a couple of water drops onto the carrier material. If the material quickly absorbs the drops, it offers good absorbency. If the water pearls off the carrier material, or if it takes a long time to be absorbed, the material offers insufficient absorbency. This can impair the effectiveness of Hotfix application.

APPLICATION USING AN APPLICATOR

Hotfix crystals can be secured with a stone setting machine using either ultrasonic or heat. The feed and application of the crystals is either fully or semi-automatic. Applicators are a cost-effective way to apply all of our hotfix products onto the carrier material.

APPLICATION USING AN IRON

In general, an iron can be used for the application of all Hotfix elements. However, as pressure and temperature can only be controlled to a limited extent, the use of a heat press is recommended. Always make sure that there are no steam vents on the sole plate of the iron. Pressure cannot be applied at these vents, and water droplets and steam have a negative effect on the application results. Always iron on a firm, flat, and even base.

HOTFIX APPLICATION ON OTHER MATERIALS

The Hotfix glue was specially developed for use with textiles. However, experience shows that Hotfix applications can also be carried out on other materials such as wood, paper or metal. In such cases it is very important to carry out application tests beforehand, and to check the surface properties (see surface tension in the “Gluing” chapter).